Hi,

I’ve been trying to implement a traction control system in Simulink by using the CM4SL resource in my PTControl, but I have some questions regarding acceleration performance.

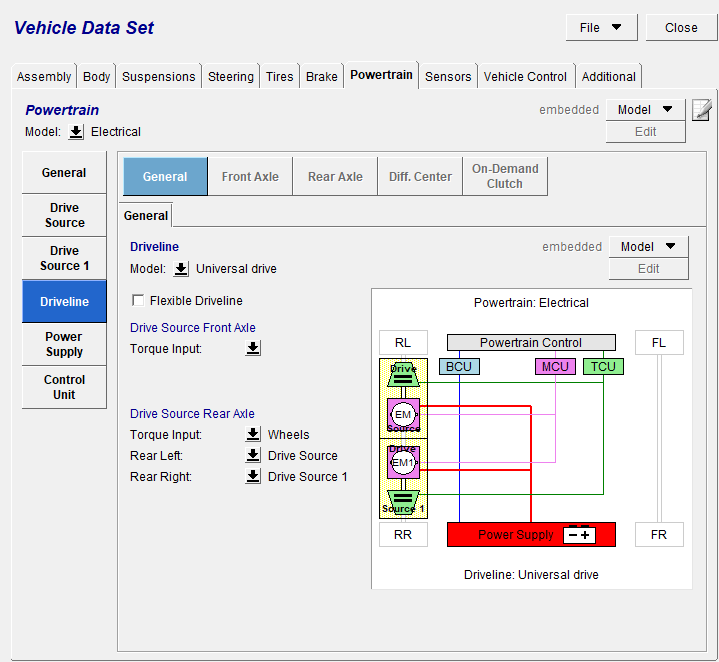

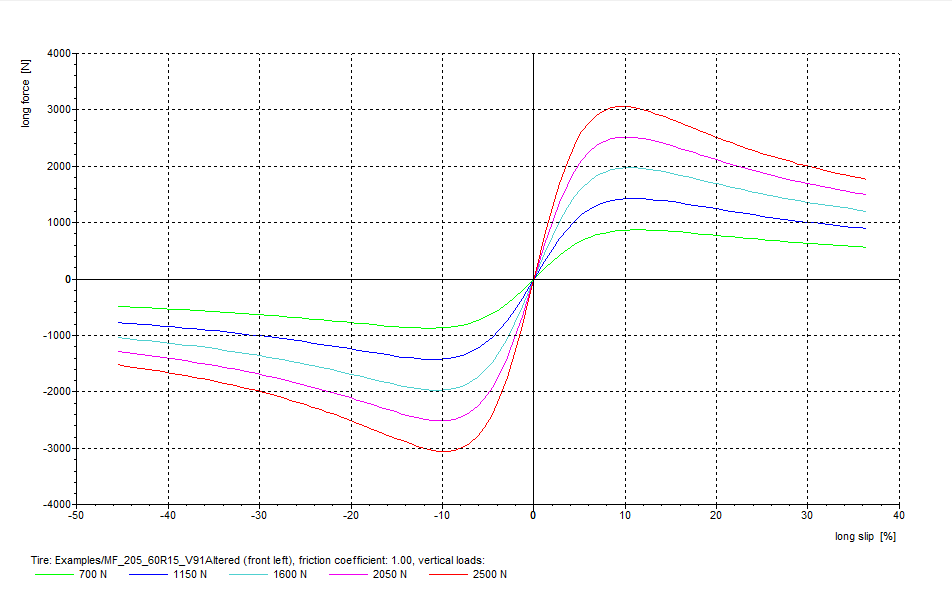

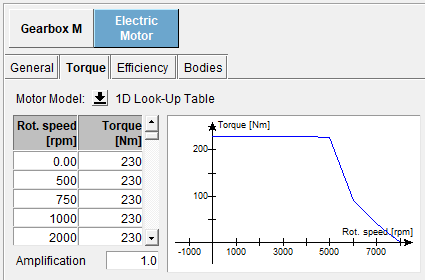

For some context, I am currently using a parametrized car from IPG for Formula Student teams, named FSEAllWheelDrive with MF_205_60R15_V91 tire. I tried using a parametrized vehicle from my team but it was just giving me problems. Anyways, I modified the Powertrain section, placing 2 motors and an Universal Driveline connecting the Motor + Gearbox directly into each rear Wheel. Besides that, I’ve made a custom hypothetical RPM x Torque curve in order to provide sufficient Torque to make the wheels spin.

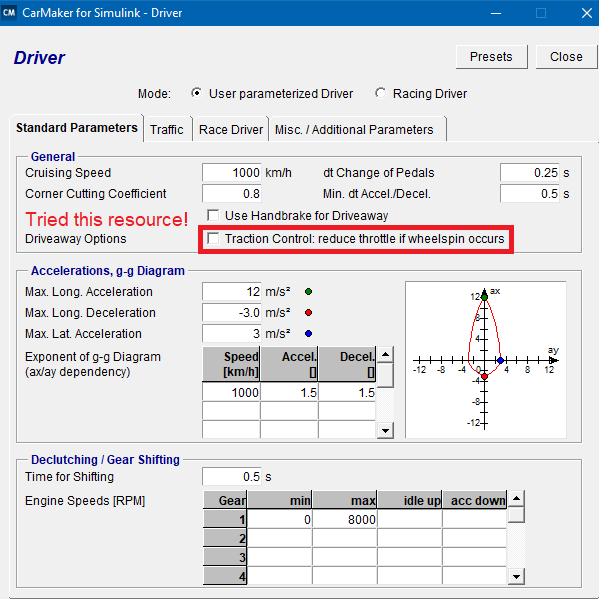

Then I proceeded to configure my IPGDriver. My goal was to simulate the effects of Traction Control on a straight line, with an accelerating Maneuver. So I configured my driver to request full throttle unitl 150m.

But after simulating this scenario with and without my Traction Control, I found that using it was slowing accelerating time, which is odd for me. Then I repeated simulations by using Carmaker provided Traction Control in Driver’s configuration. The results were the same: slower accelerating times with Traction Control.

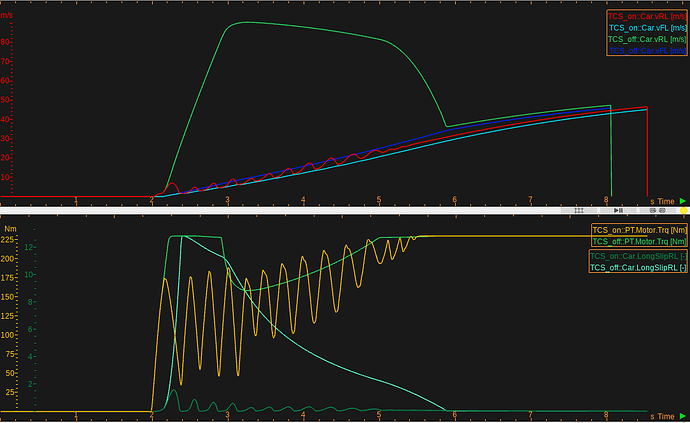

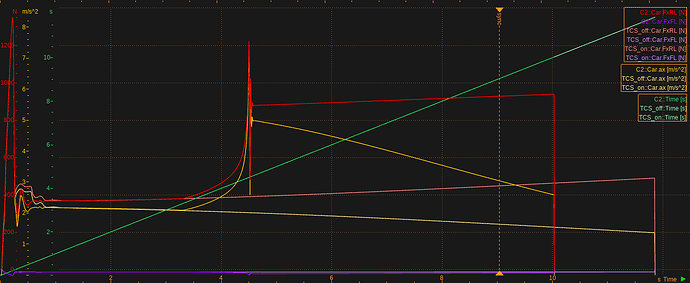

The results comparing them are below:

Analyzing the results, with TCS on, the slip ratio, and therefore, wheelspin were much lower, which proves that Traction Control is indeed working as expected.

But, and my question resides here, when TCS is off, the slip ratio is absurdly high, which, in my understanding, means that the wheels are spinning and, therefore, it should have had a negative impact on acceleration performance, which didn’t happen, as the vehicle in fact ACCELERATED faster with TCS off. I’ve been trying to come up with a solution, but without success.

Am I doing something wrong? I wanted to develop a TCS system which makes my vehicle go faster during acceleration, by minimizing slip ratios to an optimal range.

Any guidelines?